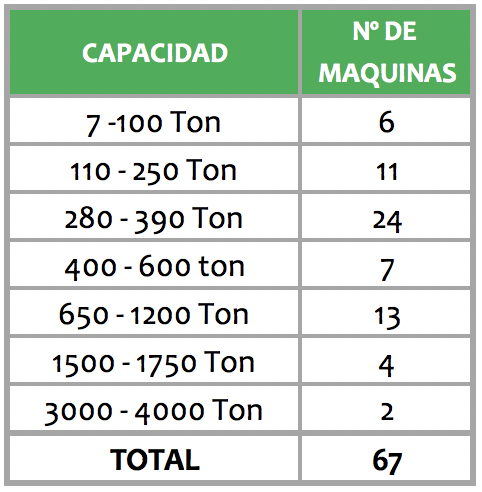

Machines

• 67 injection moulding machines with capacity from 7 to 4,000 tons of clamping pressure, and from 1 gram to 18 kilograms.

• 40% of our machines are 100% electric. Contributing to productivity and new clean technologies.

• Machine for 2-color and/or material injection.

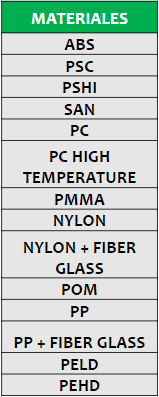

• Injection of parts in engineering materials.

• Clean area of 100% electric machines for hygiene and food products.

Robots

Currently, we have more than 60 automatisms where conventional automation is involved making use of mechanisms integrated to PLC to execute activities. In addition, integrations are made with Cartesian type industrial robots and side extraction for our injection processes. We have robots of 6 degrees of freedom for our assembly processes, adding to this a component of great importance like the artificial vision. All of the above, for a clear approach, where the implementation of this type of technology brings us closer to the 4.0 industry, thus achieving a world-class company.

Our Robots

• Cartesians: Sepro, Wittmann, Reis, Krauss Maffei, Engel, Yushin, among others.

• 4 and 6 degrees of freedom: Nachi, Motoman, Fanuc, Reis, Kuka, Scara- Epson.

Peripherals

• Additional systems for specialized injection: Sequential, gas-assisted and high-pressure air-assisted.

• We support process control through thermoregulators, temperature controls, mixers, etc.

• For the handling of raw material we have systems of supply of material by vacuum, central materials with dehumidifiers and heaters. We also have master and liquid pigment, gravimetric, volumetric dispensers that ensure precision and color stability .

• Overhead crane systems for mold assembly up to 50 tons.

• Chiller cooling systems and closed-circuit cooling systems, with tons of cooling for all machines, molds and equipment that require it to obtain stable, continuous, repetitive and highly reliable processes.

Complementary

• Printing for injected parts with pad printing (4 colors) and hot stamping.

• Ultrasonic, vibration and high frequency sealing.

• Automated systems for Label-in-Mold processes.