Manufacturing, maintenance and design

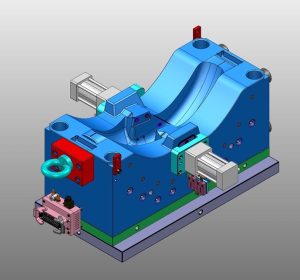

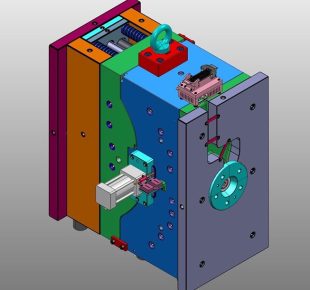

We have work areas focused on CNC machining (lathe, milling), electroerosion (erosion by penetration), adjustment and polishing (ultrasonic polishing) and the tooling design area that has the latest technology software for CNC programming and 3D design.

In our workshop we have personnel specialized in mold design, programming for the machining process, EDM, adjustment, polishing and texturing of molds.

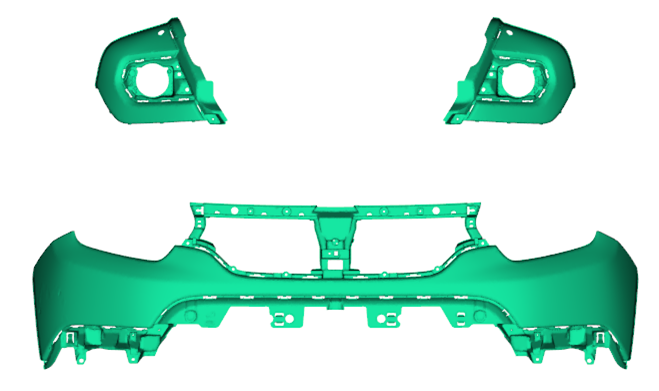

Mold Piloting

We develop production processes aligned to the specification of the product and its negotiated cost, where together with our workshop we design and manufacture tooling for its transformation.

The control and follow-up of projects and product changes is considered one of our greatest strengths.

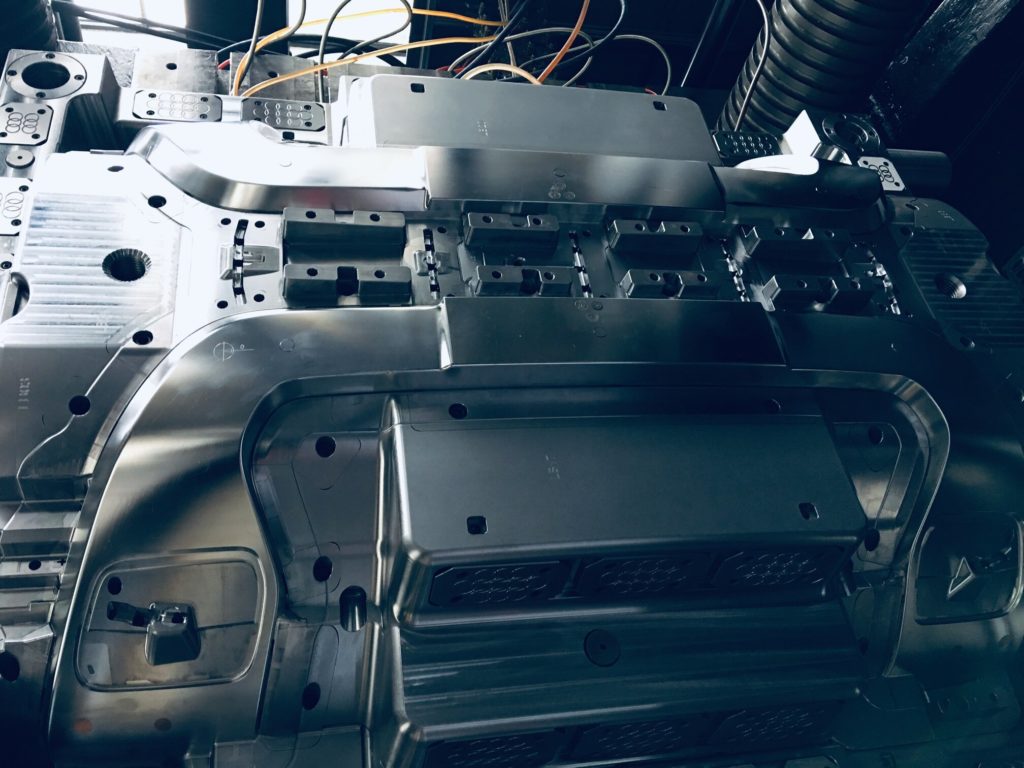

Texturized Molds

In order to meet the new technologies incorporated in the molds, we have the texturing area, which has the capacity to repair or generate new surface finishes for the molds.

This area is the result of a strategic alliance with the Brazilian company TSP, which has more than 40 years of experience in mold texturing, specialized in the development of new texture patterns, by means of state-of-the-art equipment capable of creating any pattern.

We have the experience to manufacture and/or repair any type of texture for different parts of the automotive sector, motorcycle parts, refrigerator parts, home, among others. We also have the capacity to create new textures from samples or from the customer’s imagination and specialized personnel, trained directly in Brazil.

Outside jobs